Progress Report 2025: Pathway 1

Enhancing Circularity in the PVC Value Chain

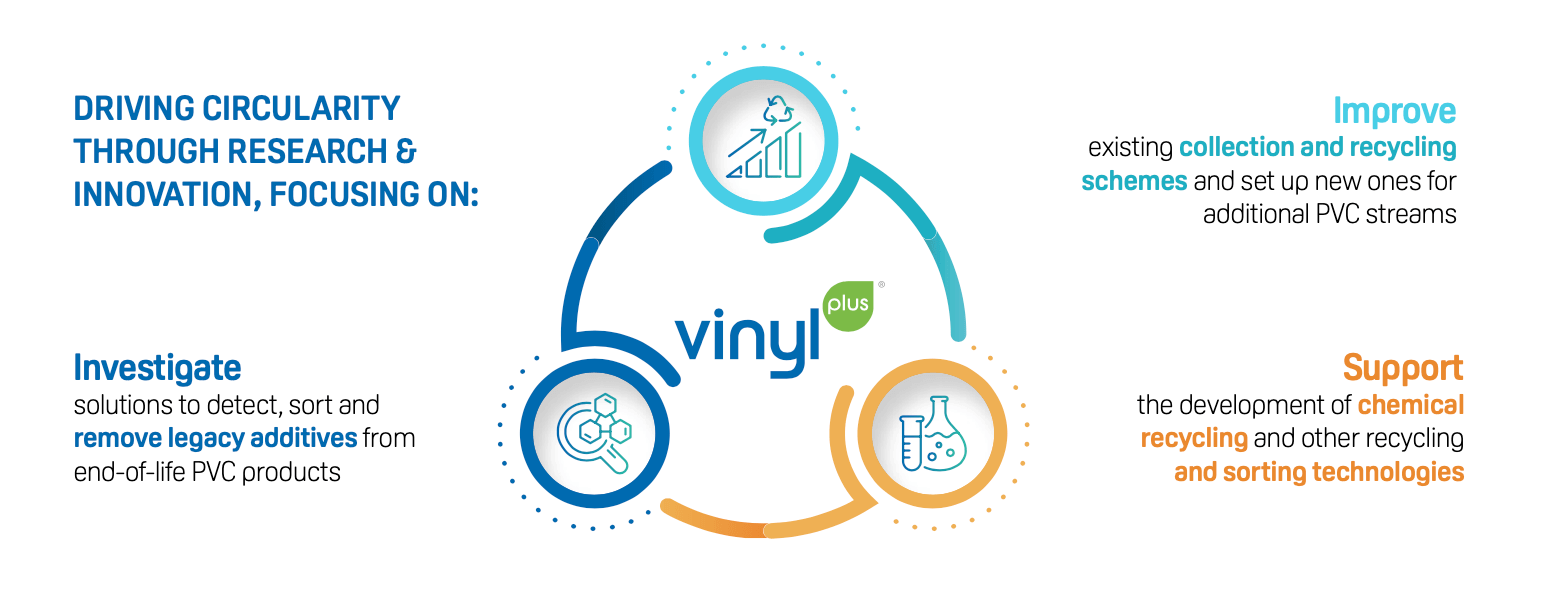

Aligned with key EU policies, such as the Chemicals Strategy for Sustainability and the Circular Economy Action Plan under the European Green Deal, VinylPlus is driving the European PVC industry towards a circular economy by enhancing PVC sustainability, increasing recycling efforts, and ensuring the safe and sustainable use of recyclates.

2024: Challenges and Resilience in PVC Recycling

The European industrial sector faced a difficult year in 2024, with industrial production down by 3.0% in the euro area. The plastics industry was hit hard by weak demand, rising energy costs, and increased imports from outside the EU. This recession was especially visible in the construction sector – PVC’s largest market – which declined across Europe.

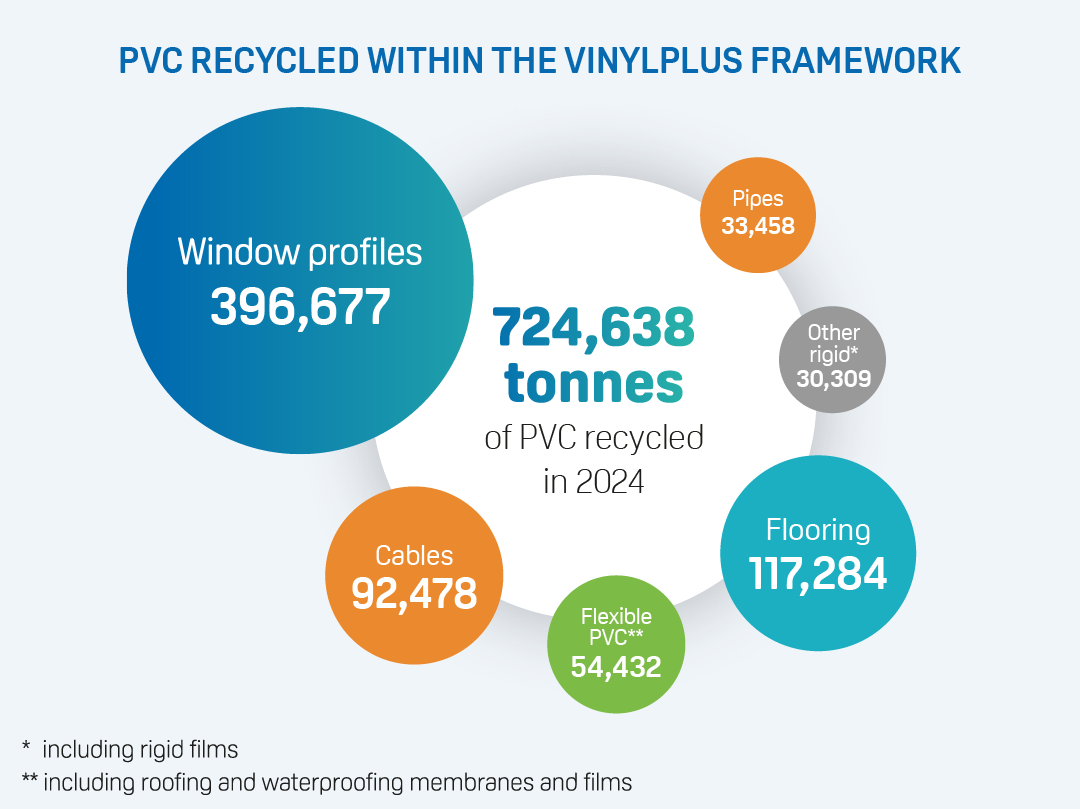

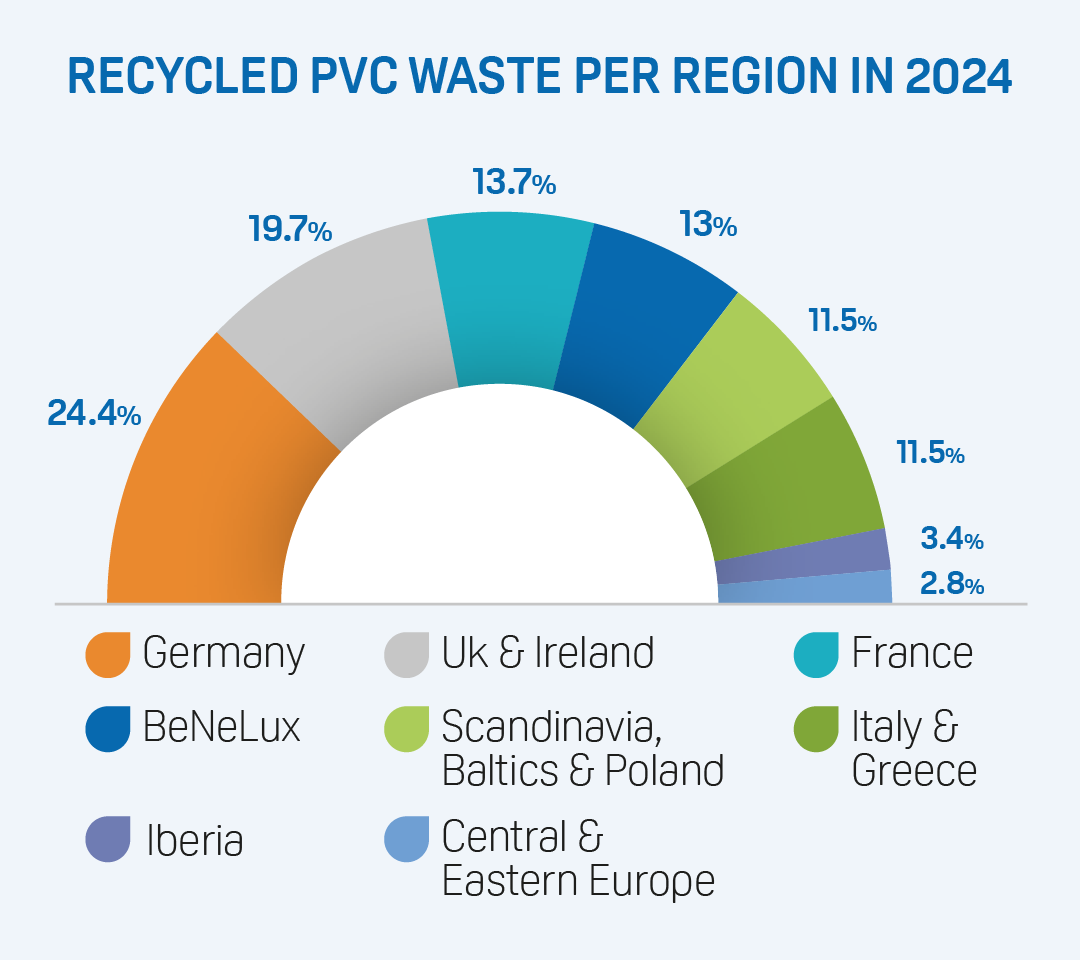

Despite these pressures, VinylPlus recycled 724,638 tonnes of PVC waste – nearly matching 2023 levels with only a 1.8% drop. Thanks to long-term investments in recycling infrastructure and circular operations by many partners, PVC recycling remained remarkably stable. Since 2000, 9.5 million tonnes of PVC waste has been recycled, saving 19.1 million tonnes of CO2, and contributing to sustain 1,500+ direct jobs in recycling plants.

VinylPlus continues to push for stronger policies to secure stable access to recyclate and level the playing field between EU and non-EU producers. Looking ahead, efforts will intensify to unlock new sources of PVC waste, supporting further investments in European recycling capacity.

OUR RECYCLING HIGHLIGHTS

Breakdown and Traceability of 2024 Recycled PVC Volumes

Of the 724,638 tonnes of PVC waste recycled in 2024, 61.4% was pre-consumer waste and 38.6% was post-consumer waste. For post-consumer waste, the amount of PVC recycled represents approximately 25% of the total PVC waste in the EU-27, Norway, Switzerland, and the UK, based on a market study and dynamic waste model developed by the consultancy Conversio in 2021. When pre-consumer waste recycling is included, this percentage increases to 35%.

The volume of PVC recyclates registered in RecoTrace® by converters increased by 4.3% compared to 2023, reaching 490,278 tonnes. With the help of RecoTrace, VinylPlus has also increased the traceability of recycled PVC establishing a clearer picture of which applications are recycled and which ones subsequently use this recyclate.

How VinylPlus Tracks PVC Waste and Recycled PVC in New Applications

Recovinyl® – the organisation set up in 2003 to facilitate PVC waste collection and recycling in the framework of the European PVC industry’s Commitments – plays a key role in monitoring, verifying and reporting PVC recycling and the use of recycled PVC (rPVC) in Europe.

Its audit framework has been recognised as one of the approved auditing systems and schemes by the Circular Plastics Alliance. Data from converters and recyclers are collected through RecoTrace – a multi-polymer online data collection system for recycled plastics in Europe. RecoTrace was originally developed by Recovinyl for PVC and then extended to cover all the main polymers.

Witnessing PVC Circularity in Practice

In 2024, European Commission representatives were invited to visit two PVC recycling facilities, Deceuninck and Raff Plastics.

Improving Collection and Recycling

The European Trade Association of PVC Window System Suppliers (EPPA) five-year action plan aims to boost PVC window recycling in France, Germany and Poland. The project made significant progress in all three countries, driving the adoption of circular economy practices and promoting the use of rPVC in new window products.

Building on work in Germany and the Netherlands in 2023, the European Plastic Pipes and Fittings Association (TEPPFA) in 2024 commissioned a material flow analysis (MFA) of plastic pipes in the UK in collaboration with the BPF Pipes Group. The study assesses material flows in the plastic pipe industry, providing a foundation for future projects to improve the collection, sorting, and processing of plastic pipe waste. It also explores the development of a holistic value chain, covering organisation, agreements, costs, and financing. The final report is expected in 2025.

The European Resilient Flooring Manufacturers’ Institute (ERFMI) project aims to advance the circular economy for PVC flooring by increasing post-consumer recycling and enhancing the use of recyclate in new products. This is done by expanding the collection of post-consumer flooring and exploring technologies to sort and remove legacy additives. One major achievement has been the successful pilot project launched in Germany in 2022 as part of the Revinylfloor initiative, aiming to increase the collection of PVC floor covering from scraps and post-consumer products.

In Italy, WREP (Waste Recycling Project) is continuing to promote the development of pilot schemes for sorting, collecting and recycling PVC from bulky urban waste and from demolition and renovation activities, in collaboration with multiutilities and recyclers.

In 2024, 14 collectors, converters and recyclers signed a memorandum of understanding (MOU) to set up a recycling working group, coordinated by VinylPlus Italia, for collaboration to boost post-consumer PVC recycling in Italy. The objective of the MOU is to encourage the development of potential synergies between companies and to promote joint innovative projects for the collection and recycling of PVC.

The consultancy Plastic Consult was commissioned to conduct three studies of key facets of the PVC industry. One delivered an up-to- date analysis of Italy’s PVC supply chain, while another delved into the factors limiting demand for rPVC in the country. The third explored the most effective applications for post-consumer rPVC sourced from building demolitions. These studies provided a clear understanding of the challenges and opportunities for PVC recycling in Italy, taking into account the current micro- and macroeconomic situation. They aim to support the achievement of VinylPlus circularity targets in Italy.

The PVC-Recyclers meet PVC-Converters project, led by VinylPlus Deutschland with AgPR, IVK Europe and Rewindo, promotes PVC recycling and rPVC uptake.

It showcases VinylPlus 2030 Commitment, recycling achievements and national initiatives, while connecting recyclers with converters to share insights into new and existing recycling processes.

In 2024, the project also provided an opportunity to present the RecoTrace data collection system and encourage recyclers and converters to register their data. Activities included networking, plant visits and bilateral talks. Key events included VinylPlus Deutschland’s participation in Fachtagung Abbruch, one of Europe’s major conferences on demolition and dismantling, in Berlin in March 2024; and two on- site meetings involving around 60 participants – one at the KKF reVinyl GmbH plant in Erfurt in September and the other at the Biotrans GmbH plant Schwerte in November.

The project helped establish and strengthen networks with recyclers and converters while also reaching out to non-partner companies, three of which became VinylPlus partners in 2024.

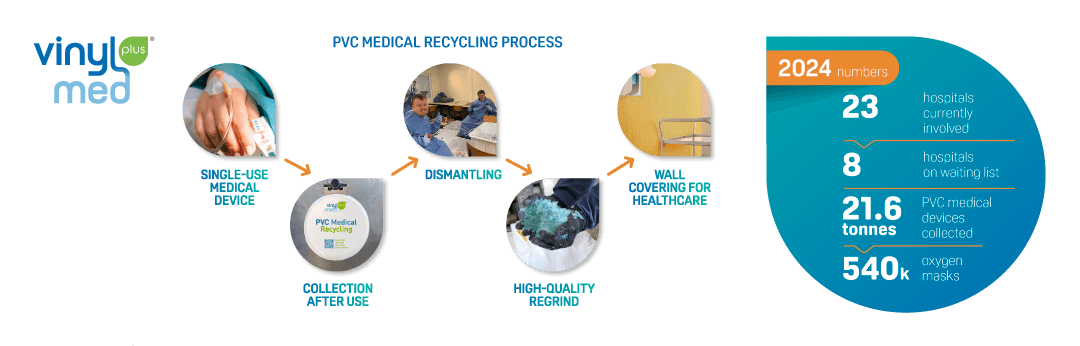

Advancing Circularity in the Healthcare Sector

VinylPlus® Med facilitates the recycling of discarded single-use PVC medical devices, such as masks and tubing, into new, durable products for healthcare settings, such as wall covering and flooring.

The programme is built on partnerships among hospitals, waste management companies, recyclers, social partners and the PVC industry. It currently involves 23 hospitals, and eight new hospitals are planning to start collecting medical PVC waste in 2025. A key achievement in 2024 was the successful integration of the recycled PVC produced in the framework of VinylPlus® Med in products from Vescom (wall coverings) and Gerflor (homogeneous floor coverings). Major efforts were dedicated to improving the quality and cleanliness of the collected materials, and hospitals were provided with stricter sorting instructions to prevent contamination.

In Belgium, an additional waste hub – the De Loods De Nekker – was involved in the project. It began dismantling PVC medical waste in November 2024 and had processed around 1 tonne by the end of the year, which was redirected to recyclers for further processing.

In France, many hospitals expressed interest in the VinylPlus® Med programme. A feasibility study was launched in partnership with Terra, experts in the circular economy, and Medtronic a global healthcare technology leader. The study focuses on the combined collection of soft PVC medical devices and rigid PVC video-laryngoscope blades. Collaboration with MédiPôle Villeurbanne, the largest clinic in France, further expanded the project’s scope, in particular to dialysis lines.

The VinylPlus® PharmPack programme aims to demonstrate the recyclability of pharmaceutical blister packaging made of aluminium and PVC.

It focuses on developing recycling technologies to produce rPVC suitable for reuse in film calendaring processes. In 2024, larger-scale trials were successfully conducted at Fraunhofer IVV. using dissolution technology to separate PVC from aluminium.

The rPVC obtained was suitable for producing rigid films, which were tested and converted into blisters by Liveo Research and Perlen Packaging. This project confirmed that the dissolution technology could produce rPVC of sufficient quality for new rigid films for pharmaceutical blisters, while the rPVC produced with existing mechanical recycling can be used in other applications, such as profiles and pipes. A final scientific paper is expected in 2025.

Safe and Sustainable Use of Additives

The VinylPlus commitment to circularity involves providing scientific evidence to demonstrate safe use of additives and of PVC articles containing recyclates with legacy additives. It also includes supporting R&D projects to detect, sort, reduce, or remove legacy additives in PVC waste streams. For the past two decades, the European PVC industry has been working not only on solutions for legacy additives but also on methods to ensure that additives used in new PVC products result safe and high-performing also in the foreseeable future. VinylPlus will continue to support research and studies to provide users and consumers with safe and sustainable PVC products, in line with upcoming European initiatives, including the Ecodesign for Sustainable Products Regulation (ESPR).

For a Safe Use of Additives and Recyclates With Legacy Additives

It assessed plasticiser concentrations and the kinetics of release, both with and without agitation (to simulate sea waves). It focused on plasticisers, such as DINP, DIDP, DOA, and DOTP, which are currently under scrutiny from NGOs, ECHA and European decision makers. Preparation is ongoing of the scientific paper to be published in a peer-reviewed journal.

Detecting and Sorting Legacy Additives From PVC Waste Streams

It builds on two earlier WREP and PVC4Cables projects: one developed handheld NIR detectors to sort legacy additive-containing PVC waste, and the other studied XRF feasibility for inline detection of lead and other contaminants. The new project aims to build an inline pilot plant to sort PVC waste—including cables, pipes, profiles and flooring—containing phthalates and heavy metals. Combining XRF and NIR, the system will detect lead, MCCPs, and phthalates. Initial tests by Phoenix RTO confirmed industrial viability, and the handheld NIR device will be upgraded with AI for enhanced identification.

ECHA INVESTIGATION REPORT ON PVC AND PVC ADDITIVES

As reported in last year’s VinylPlus Progress Report, the European Chemicals Agency’s (ECHA) Investigation Report on PVC and PVC Additives was published in November 2023, followed by VinylPlus’ comprehensive response in February 2024.

The Investigation Report was presented to and discussed in both the European Parliament’s ENVI Committee and at the meeting of the Competent Authorities for REACH and CLP (CARACAL) in March 2024. The second of these meetings featured participation by EU Member States, industry representatives, and NGOs.

Also in March, VinylPlus met with the European Commission to discuss its response to ECHA’s findings. The Commission acknowledged some factual errors in the ECHA report, particularly regarding organotins and recycling, but confirmed that the report would not be amended. It clarified that the ECHA report should be viewed within the broader context of ongoing initiatives and confirmed that ECHA’s recommendations would be addressed either under REACH or through other regulatory tools. The Commission also expressed appreciation for VinylPlus’ research efforts to address the data gaps identified by ECHA.

Confirming its commitment to continue working with regulators, VinylPlus commissioned several new studies in 2024, which are currently ongoing.

Webinar

In April 2024, VinylPlus organised a webinar, with the participation of Simone Doyle of ECHA, to present the Investigation Report to and discuss it with the European PVC value chain. It attracted more than 300 participants.

Supporting Innovative Recycling Technologies

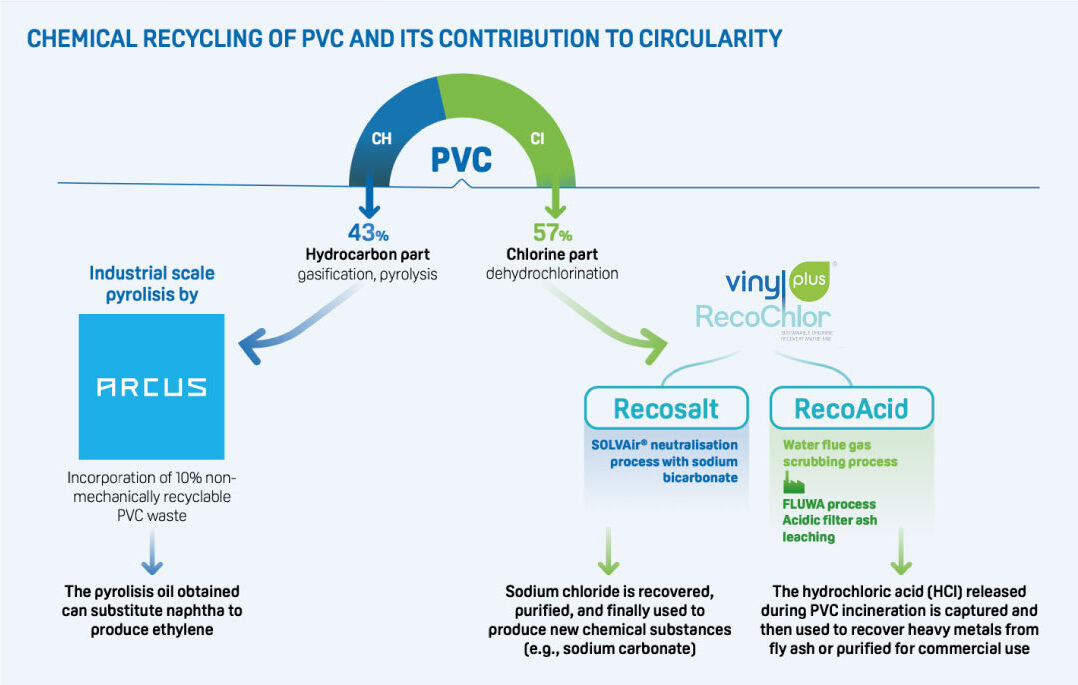

Mechanical recycling remains the most widely used method for processing PVC waste today. To continue progressing towards circularity and reach ever more ambitious recycling commitments, the industry is focused on developing advanced recycling technologies to tackle the residue PVC waste that cannot be mechanically recycled, such as PVC containing legacy additives and composite PVC products. These technologies include for example dissolution, extraction, pyrolysis and gasification.

34 DIFFERENT RECOVERY OPTIONS INVESTIGATED SINCE 2000

Assessing chemical recycling technologies

Arcus

In 2024, trials were conducted at ARCUS Greencycling Technologies’ chemical recycling facility in Frankfurt, Germany, to demonstrate that adding non-mechanically recyclable PVC waste streams (up to 10%) does not negatively impact the pyrolysis process. The results showed the successful production of good-quality pyrolysis oil on an industrial scale, confirming that “the pyrolysis oil produced from a mixed-plastic waste stream including 10% of PVC waste is of similar quality to an oil obtained without the addition of PVC”. This oil can subsequently be used as a feedstock in steam crackers to produce olefins, contributing to a more circular economy for plastics.

VinylPlus® RecoChlor

In this process, selected PVC waste streams are thermally decomposed in waste-to-energy (WTE) plants, in which chlorine is recovered either as sodium chloride (RecoSalt, dry process) or as diluted hydrochloric acid (RecoAcid, wet process). The hydrocarbon part is recovered as energy.

VinylMet

It is being conducted at the WTE plant in Basel, Switzerland and is co-funded by the Swiss Federal Office for the Environment (FOEN). In December 2024, a 24-hour test incineration of PVC sorting residues was conducted to prepare for a larger-scale trial in 2025. The test compared residues from two incineration lines: one fed with PVC wast and another acting as a reference. Early results showed successful controlled feeding and effective sampling of residues. The project will continue in 2025 with longer trials, with the aim of optimising heavy metal recovery and improving PVC recycling efficiency in WTE plants.

Mechanical recycling is our preferred option. However, it should be acknowledged that advanced chemical recycling technologies could complement mechanical recycling when this is not possible, helping recover marketable raw materials and potentially achieving both environmental and economic gains. It would be helpful if regulators defined the conditions under which these technologies could be applied cost-effectively, for example, by using the mass balance concept.

Sorting and separation technologies for complex PVC products

EUPolySep

This innovative process enables the delamination and separation of polymers from composite structures, facilitating subsequent recycling. In 2024, tests on composite PVC started at the pilot plant installed at the Centexbel (CTB) facility in Grâce-Hollogne, Belgium. The project was scheduled to be concluded in 2025, at which point the findings would be reviewed to assess whether further development of separation technologies is needed.

Nevertheless, the project encountered some delays related to the fine-tuning of the operating parameters and the installation of the pilot plant. Whilst the results so far are encouraging, partners will evaluate in Q2 2025 what potential process design or optimisation adjustments should be made and determine the next steps. The full-scale evaluation of the technology at an industrial pilot scale will then likely be finalised in 2026.

Prioritising Circularity Through Eco-Design

The PVC industry continued to advance circularity through eco-design in 2024 as part of its commitment to sustainable development, and in line with the European Commission’s Standardisation Mandate M/584,45 which supports the European Strategy for Plastics in a Circular Economy.

EPPA led the development of Plastics – Design

for recycling of PVC based profiles for construction products FprEN 18066 in the CEN Technical Committee 249 (‘Plastics’) WG21 (‘Profiles for windows and doors’). Released in early 2024, this design-for- recycling (DfR) standard set guidelines for designing PVC-based profiles, such as windows and doors. These prioritise recyclability, recycled content, and product quality, thus ensuring that designs meet sustainability objectives.

ERFMI contributed to the release of CEN/TS 18075:2024 Resilient, textile, laminate and modular mechanical locked floor coverings – Circular economy and sustainability – Recommendations/guidelines for design, a technical specification for floor coverings, including PVC flooring. This document provides guidelines on how to design products to optimise reuse, recyclability and sustainable material sourcing for all flooring product groups covered by CEN/TC 134.