VinylPlus® PharmPack

Sustainable Development of PVC Pharma Blister Packaging

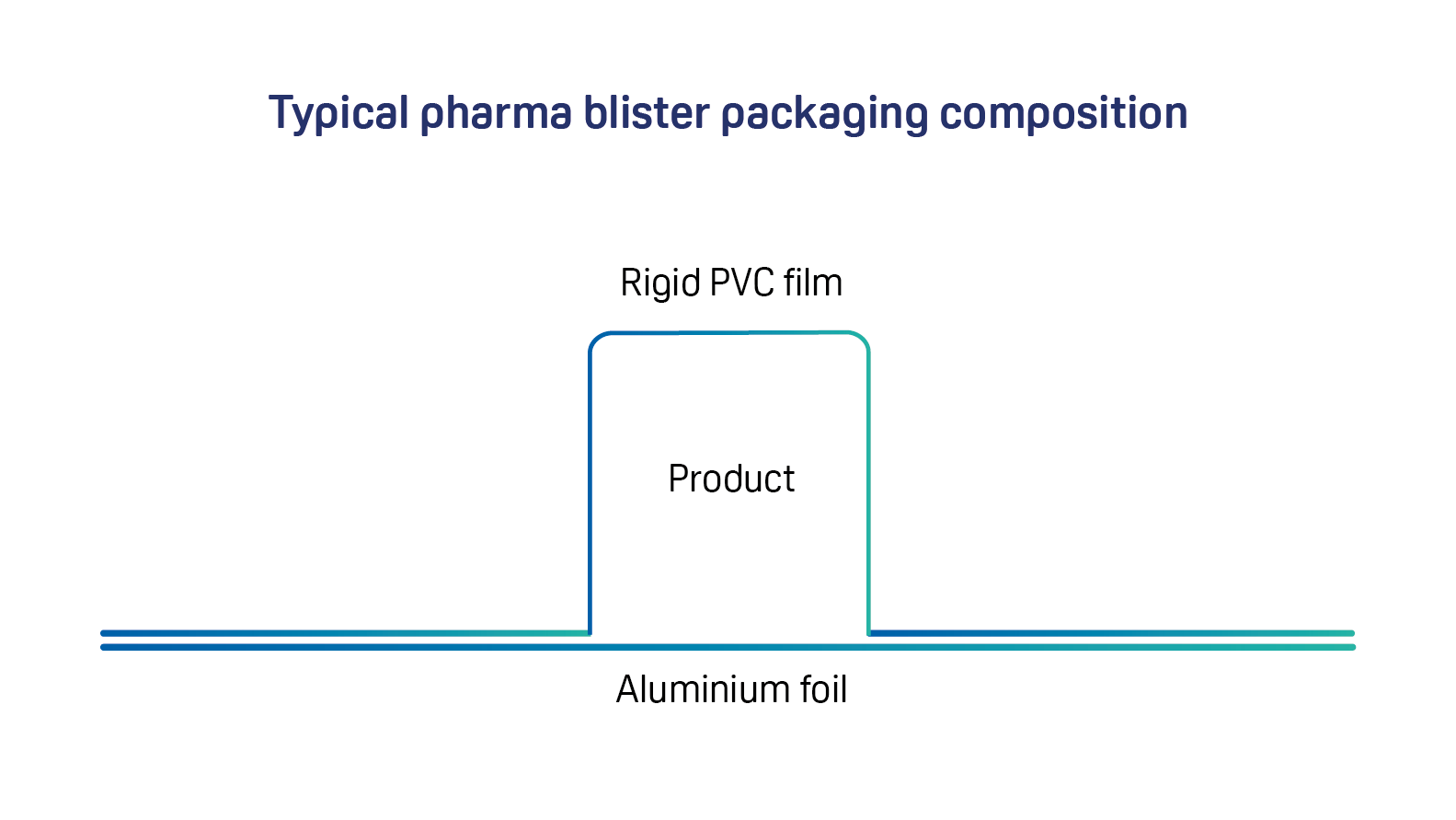

In the pharmaceutical industry, packaging plays a pivotal role in preserving the integrity of medications, ensuring their safe delivery to patients, and extending shelf life. In Europe, blister packaging is favoured. Pharma blister packaging is typically made from PVC composite films with aluminium foil, which protect the content reliably and safely from damage for example by moisture, and allow an easy dose of medication. Now, leading PVC film manufacturers, recyclers and VinylPlus® have come together in the joint project VinylPlus® PharmPack for the sustainable development of PVC pharma blisters packaging.

Pharma Blisters in the Healthcare Sector

PVC products have been successfully used in healthcare for decades. These include blister packaging for pharmaceuticals which are mainly made from PVC composite films with aluminium foil. They offer a high degree of safety, through excellent barrier properties and allow to take the pharmaceutical individually without impacting the shelf life of the remaining tablets. They keep them sterile and reliably protected against germs, bacteria, moisture, and oxygen. Due to these positive product properties, PVC is the leading material in pharma blister packaging.

Recycling Initiative Launched

Pharmaceuticals that are no longer needed must be disposed of safely. This also applies to used pharma blisters. This post-consumer waste is therefore incinerated with energy recovery. Pre-consumer waste that is generated in the manufacturing process of films, blisters, and the packaging of pharmaceuticals can be recycled mechanically. The VinylPlus PharmPack initiative includes all steps of the value chain – from collection, transport, and recycling of waste to the manufacture of new products from recycled PVC. The aim is to conserve valuable resources, optimise the carbon footprint of the products, and support pharmaceutical companies in achieving their sustainability goals while saving costs.

The Recycling Process

Collection

Punched grids, empty blisters, and materials from film and packaging production are collected and transported to recycling partners.

Milling

The pre-consumer waste is milled.

Separation into PVC

The pre-consumer waste is milled and separated into its main components.

Separation into aluminium

The pre-consumer waste is milled and separated into its main components.

Use of recycled PVC

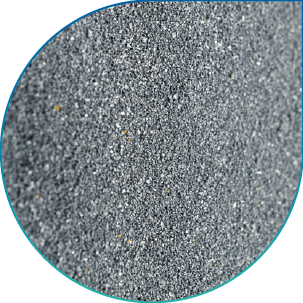

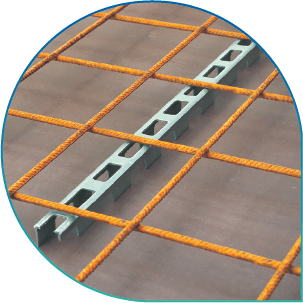

Among other things, the fine PVC regrind is processed into spacer profiles for the construction industry (image courtesy of MAX FRANK Gruppe).

Use of recycled aluminium

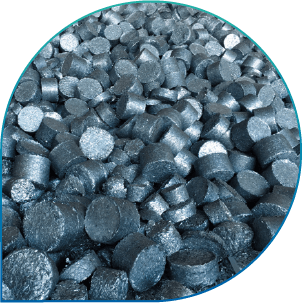

Aluminium pellets are used in the metal industry such as new engine blocks.