Moving the PVC industry to a low-carbon circular economy

2015 is a crucial year for global action to secure a sustainable future for all. Two high-level international meeting taking place in Autumn will set the global agenda and chart the road ahead to 2030: the United Nations Summit to adopt the post-2015 development agenda, in New York, in September; and the Paris Climate Summit (COP21) in December.

Poverty eradication, changing unsustainable and promoting sustainable patterns of consumption and production, and protecting and managing the natural resource base of economic and social development are the overarching objectives of the Sustainable Development Goals (SDGs) that UN Heads of State and Government will adopt in September. The SDGs will be holistic and universal, and everybody will have to contribute. COP21 will be a crucial conference, as it needs to achieve a new international agreement on climate, applicable to all countries, with the aim of keeping global warming below 2°C. A universal, legally binding, agreement that will enable to combat climate change effectively and boost the transition towards resilient, low-carbon societies and economies.

Tackling climate change and fostering sustainable development agendas are two mutually reinforcing sides of the same coin. Governments, institutions, NGOs, industry, public and private organisations, all are called to address these global challenges.

And also the European PVC industry has a role to play. “It would be too much to claim that that our value chain can save the world climate, but as our products are versatile due to their favourable footprint, durability, longevity, energy and resource conserving properties, we believe we are part of the solution and not of the problem” said VinylPlus Chairman, Michael Träger at this year’s Vinyl Sustainability Forum 2015, in Cannes, France.

More Vinyl, Less Carbon

The theme of this year’s Vinyl Sustainability Forum – ‘More Vinyl, Less Carbon’ – summarises the challenge ahead of PVC for the coming years, but also how VinylPlus Voluntary Commitment is already contributing to address climate change, improving product sustainability and moving the European PVC industry towards a circular economy.

“In the race for sustainability the laggards will lose. We see the VinylPlus initiative as the forerunners and the role model for a global standard of the industry” said Christophe Yvetot, from the United Nations Industrial Development Organization (UNIDO) at the Vinyl Sustainability Forum 2015

Doing better with less

According to the principles of a circular economy described in the European Union’s roadmap to a Resource Efficient Europe and the Sustainable Consumption and Production Action Plan, companies have to re-think and re-design their products and processes to reduce raw materials and energy consumption, extend their life-cycle, and re-use and recycle as much as possible.

PVC is one of the most widely used plastics in the world. Because it is so versatile, PVC is used extensively in a broad range of industrial, technical and everyday applications. PVC is intrinsically a ‘low carbon’ plastic (57% of its molecular weight is chlorine derived from common salt, 5% is hydrogen and 38% is carbon, compared for example to 86% carbon in polyethylene and 92% carbon in polystyrene), and it consumes less primary energy in the manufacturing phase than other commonly used plastics. There are several intrinsic benefits that PVC as a material brings, but of course, as any material and human activity, it has a carbon footprint and an impact on the environment.

Through the VinylPlus initiative, the European PVC industry seeks to reduce progressively GHG emissions along the entire production chain. This identifying and measuring the GHG footprint of all components and production processes; establishing GHG reduction targets; endeavouring to increase use of renewable energy and of technologies to enhance the efficiency of materials used; and implementing these engagements with business partners and stakeholders.

Initiatives, in this sense, are already in place, including for example the target of a 20% reduction by 2020 of the energy consumption for PVC resin production (-10.2% to date); the definition of a new methodology called ‘EPDplus’ to evaluate the use of substances utilised as additives in PVC products from the perspective of sustainable development which integrates the current standard Environmental Product Declarations (EPDs) with TNS criteria for sustainability; the assessment study on the feasibility of PVC resin production with ethylene from biomasses, thus decoupling plastic production from oil consumption.

More recycling, better recyclate PVC

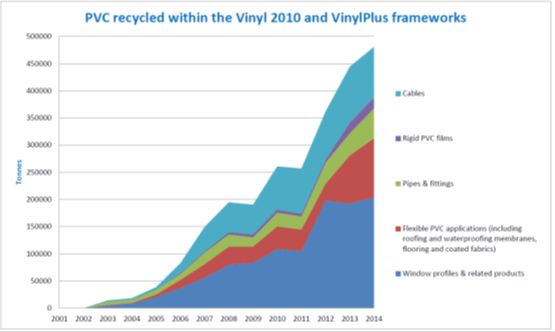

“VinylPlus can be considered as a flagship for the circular economy” said the European Union’s Director of DG Growth Gwenole Cozigou at the Vinyl Sustainability Forum 2015. The European PVC industry is managing waste streams with a controlled-loop approach, and although there is still work to do in this area to reach the VinylPlus target of 800.000 tonnes of PVC recycled per year by 2020, PVC recycling is becoming an economically viable business. In 2014, the amount of end-of-life PVC recycled within the VinylPlus framework was 481.000 tonnes, equivalent to around 20% of the total waste arising from PVC, based on a 2013 estimate by the German market research company Consultic.

Using recycled PVC helps meet resource-efficiency targets and allows the preservation of natural resources. It has been calculated that CO2 savings of up to 92% are achieved when PVC is recycled: recycled PVC’s primary energy demand is typically between 45% to 90% lower than virgin PVC production (depending on type of PVC and the recycling process). Furthermore, according to a conservative estimation, for each kg of PVC recycled, 2 kg of CO2 are saved. On this basis, CO2 savings from PVC recycling in Europe is now at around 1 million tonnes of CO2 saved per year.

In addition, according to a study by TAUW, an independent European consulting and engineering company, on average one employee is needed to recycle 500 tonnes/year of PVC. Hence the 481.000 tonnes of PVC recycled in 2014 contributed to the creation of about 1,000 direct jobs in recycling plants.

Less emissions and safe transport

VinylPlus is seeking to reduce GHG emissions due to transportation at all stages of the value chain, working with transport providers in developing safe, transparent and effective transportation models and measuring and reporting progress to stakeholders, with a view to identifying further efficiencies.

Sustainable consumer use

Due to its relatively light weight, durability and stability, PVC can offer energy, cost and material efficiency gains for sectors such as building and construction, water distribution, health and transportation. PVC products can significantly contribute to energy efficiency improvement in buildings (the British Fenestration Rating Council, for example, estimates that over 80% of the windows with ‘A’ energy rating are PVC). Innovation, eco-design and increased use of PVC recyclates are further enhancing PVC products contribution in this direction, as highlighted by converters at the Vinyl Sustainability Forum 2015.

VinylPlus aims to help end users of PVC products to reduce their own GHG emissions, working with stakeholders (including retailers) to identify sectors, products and services where PVC offers climate and other sustainability benefits.

PVC products save energy during use, and are vital in renewable energy technologies, some examples are transparent pipes for photo-bioreactors, photovoltaic cells on reflective PVC roof membrane, wind turbine blades, pressure pipes in geothermal projects, pipes in biogas plants or solar pond liners.

Due to its relative ease of use, PVC offers convenience and economic effectiveness for many trades applications, thereby assisting many Small and Medium Sized Enterprises (SMEs) with job creation and economic growth.

Competitive business environment and predictable policy framework

VinylPlus is delivering on its commitments, and this beside the fact that the European business environment has evolved – due to the economic crisis, from which we should progressively be getting out, but also to some regulatory burdens that have emerged over time. It’s important, though, that the EU PVC industry remain competitive to be able to continuing investing in the VinylPlus programme and contributing to the transition towards a resilient, low-carbon society and economy. Competitiveness of the EU PVC depends on two main factors – competitive energy prices and competitive feedstock prices – and currently the EU energy and climate policy does not support industry competitiveness at global level.

The European PVC industry hopes that a strong global agreement at the COP21 Climate Summit in Paris set the reliable and predictable policy framework required to tackle climate change at the scale needed, while avoiding economic and competitive distortions and preventing carbon leakage between regions and sectors.

Predictable and reliable policy frameworks are critical for industry’s long-term investments in research, innovation and technological development that can foster transition towards a low-carbon circular economy and sustainable development.

Addressing global challenges

“UNEP welcomes all Sector initiatives such as VinylPlus, which recognize the challenges, set targets, engage stakeholders and demonstrate progress. 2015 will set the sustainability agenda through 2030 and beyond. No matter how you react, the trends that are driving the planet are driving the market. The private sector can see this as a new set of regulations, restrictions and red tape, or as a historic, immediate opportunity to innovate, grow new markets, and build new relationships with customers and other stakeholders to help society meet the challenge of change. UNEP stands ready to work with those visionaries.” said Arab Hoballah, Chief Sustainable Lifestyles, Cities and Industry of the United Nations Environment Programme (UNEP) at the Vinyl Sustainability Forum 2015.

Current and future social, environment and economic challenges are interlinked and must be addressed through an integrated approach, with governments, business, civil society and the UN system working together to achieve transformational breakthroughs.

VinylPlus achievements so far well position the European PVC industry and products to be part of the solution to climate mitigation and sustainability. The VinylPlus mid-term review of targets in 2015 gives the PVC industry the opportunity to place its sustainability programme in the context of ongoing environmental and socio-economic developments, taking into account valuable inputs and contributions from stakeholders, with a view to enhancing its contribution to addressing global challenges.

Brigitte Dero, VinylPlus General Manager