Progress Report 2023: Pathway 1

1.1 Advancing our circularity ambitions

1.1 Advancing our circularity ambitions

In line with the relevant EU policies, such as the Chemicals Strategy for Sustainability and the Circular Economy Action Plan under the European Green Deal, VinylPlus is leading the European PVC industry towards a circular economy, by improving the sustainability performance of PVC, boosting recycling and ensuring the safe and sustainable use of recyclates.

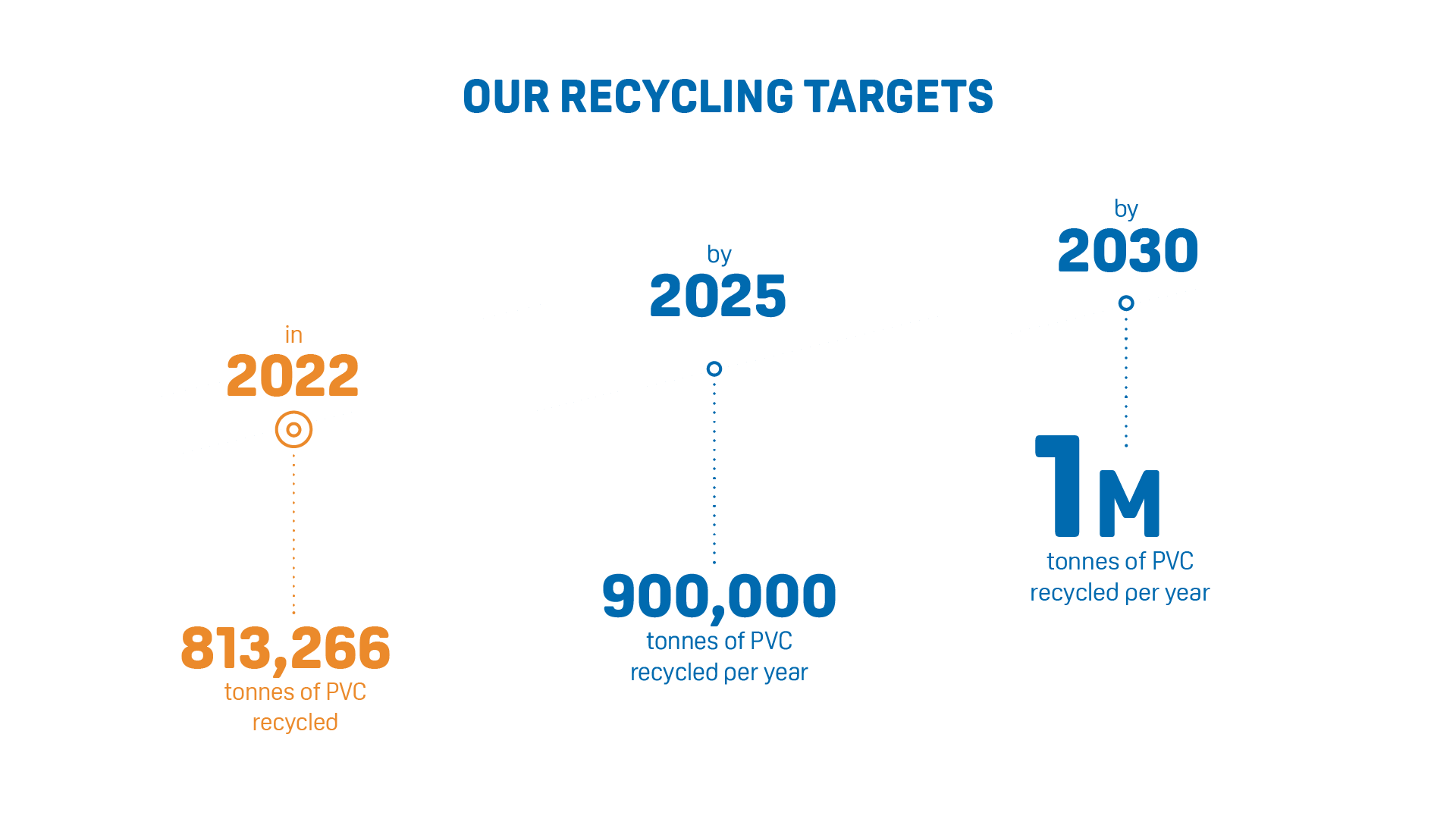

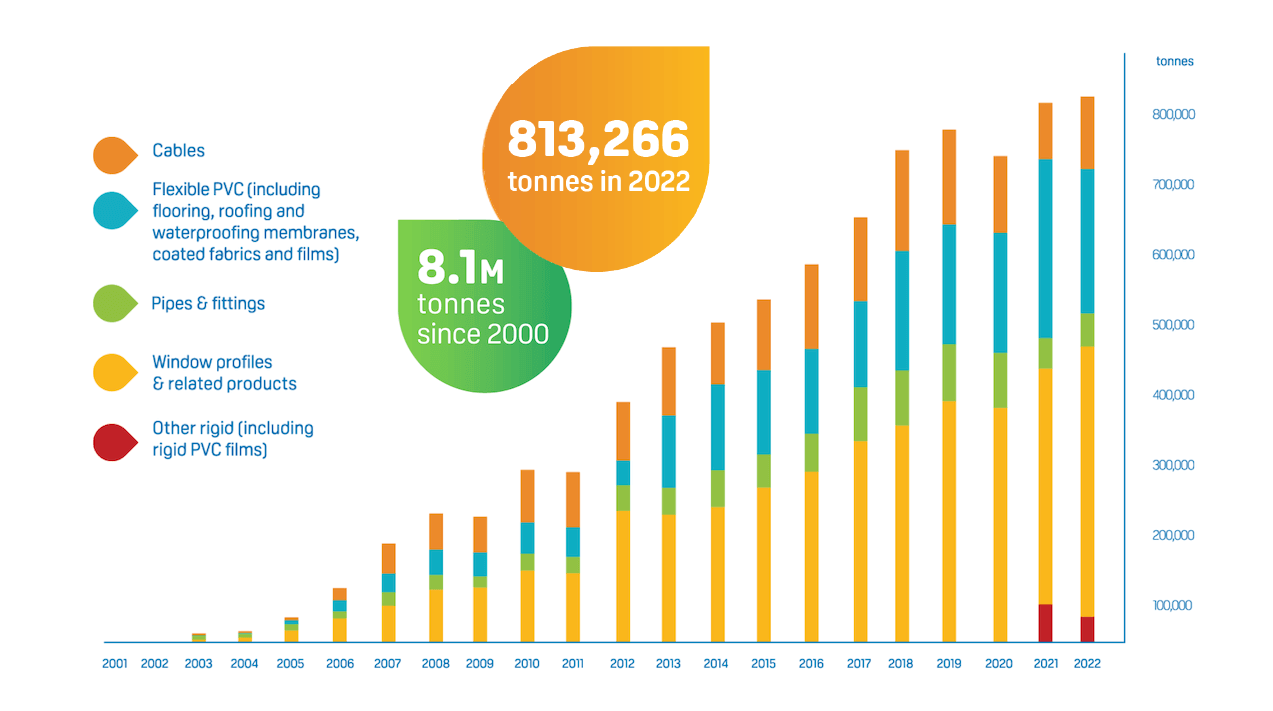

Our recycling achievements

tonnes PVC recycled since 2000

tonnes CO2 saved since 2000

direct jobs in recycling plants

PVC recycled within the VinylPlus framework

In 2022,

813,266 tonnes of PVC waste were recycled within the VinylPlus framework,

of which 62.4% was pre-consumer waste

and 37.6% post-consumer waste.

The amount of PVC waste recycled represented around 27% of the total PVC waste generated in 2022 in the EU-27, Norway, Switzerland and the UK.

Demand for recycled PVC (rPVC) remained very high until the third quarter of the year, in a very competitive market. The registered uptake of rPVC from converters reached 561,795 tonnes in 2022, a 24.8% increase compared to the previous year.

This result was achieved also thanks to the extension of the network of converters utilising the RecoTrace™ data collection system.

%

increase in rPVC uptake between 2021 and 2022

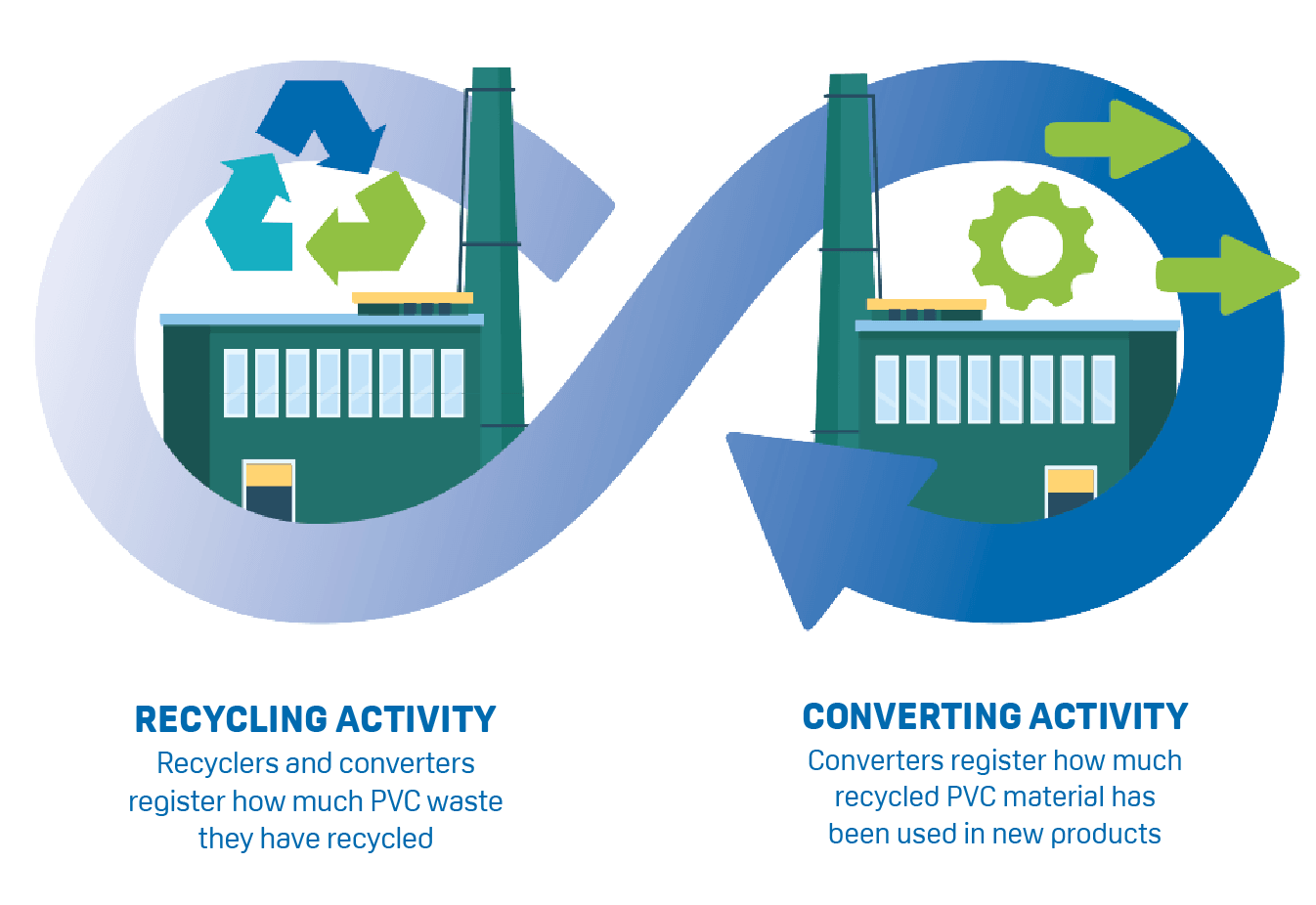

Recovinyl® monitors, verifies and reports European PVC recycling and the use of recycled PVC in Europe.

The European Commission has recognized Recovinyl® and its data collection system RecoTrace™ as one of the approved data collectors for the Circular Plastics Alliance (CPA). RecoTrace™ was used as a blueprint and became the first system to comply with the CPA monitoring requirements and Audit Protocol.

The Circular Plastics Alliance has committed to increase the EU market for recycled plastics to 10 million tonnes by 2025. VinylPlus plays an active and decisive role in both the CPA Construction Working Group and the CPA Monitoring Secretariat with its efforts to increase PVC recycling in the EU.

The mechanism established by the CPA to track progress is the first ever EU-wide transparent and trusted monitoring system, thanks to the auditing and the traceability of both the platforms and the data.

PROVIDES

reliable

traceable

audited

DATA ON PVC RECYCLING AND THE USE OF RECYCLED PVC IN NEW PRODUCTS

Providing accurate estimates of recycling potentials

In 2022, the dynamic waste model developed by the consultancy Conversio for the PVC industry was approved for use by the converter sectors, which were then provided with specific training sessions.

The Conversio model is a powerful and unique tool for the plastics industry, as it enables an estimation of the annual quantities of post-consumer PVC waste generated in Europe by 20 product categories.

Conversio data estimates that 35% of PVC waste is currently being recycled in Europe.

Circularity is also progressing in the healthcare sector thanks to programmes such as VinylPlus® Med in Belgium and VinylPlus® PharmPack in Germany.

Research, innovation and best practices

› Improving collection and recycling

With the aim of increasing the amount of post-consumer windows recycled and rPVC-U (unplasticised recycled PVC) used, EPPA developed a five-year action plan, focusing on France, Germany and Poland – the three countries with the most promising opportunities to increase recycling further.

![]()

In France, the EPPA partner UFME expanded to the number of signatories of its label FERVAM (Filière Engagée pour le Recyclage et la VAlorisation des Menuiseries), which values best practices in the recycling of windows. Through its participation in VALOBAT, UFME is committed to supporting the doors and windows sector in waste management.

![]()

In Germany, the partnership with Rewindo helped to build closer relationships with politicians, authorities, converters and recyclers, thanks also to the 20th anniversary of the Rewindo scheme in summer 2022. There were intense promotion and communications activities for window recycling involving the entire supply chain and with civil society.

![]()

In Poland, an organisational and managerial structure was implemented, aimed at improving infrastructure increase the collection and recycling of post-consumer windows.

WREP, the Italian Waste Recycling Project, is promoting the development of pilot schemes for sorting, collecting and recycling PVC from bulky urban waste in collaboration with multi-utilities and recyclers. To date, the operational phase has involved five recyclers and five multi-utilities in the northeast of Italy, in Lazio and in central Tuscany.

Another six utilities and recyclers have also expressed their interest in joining the project.

A handheld device to sort PVC from other plastics using near-infrared hyperspectral technology (NIR) developed by Phoenix was tested in the collection centre of Progetto Ambiente (the utility of Aprilia, Lazio). The device enabled the detection and separation of other plastics (around 1%) from PVC, thus reducing the presence of contaminants to close to zero. In addition, the handheld device software was developed further to detect the presence of orthophthalates in PVC for medical applications and been used in the VinylPlus® Med programme.

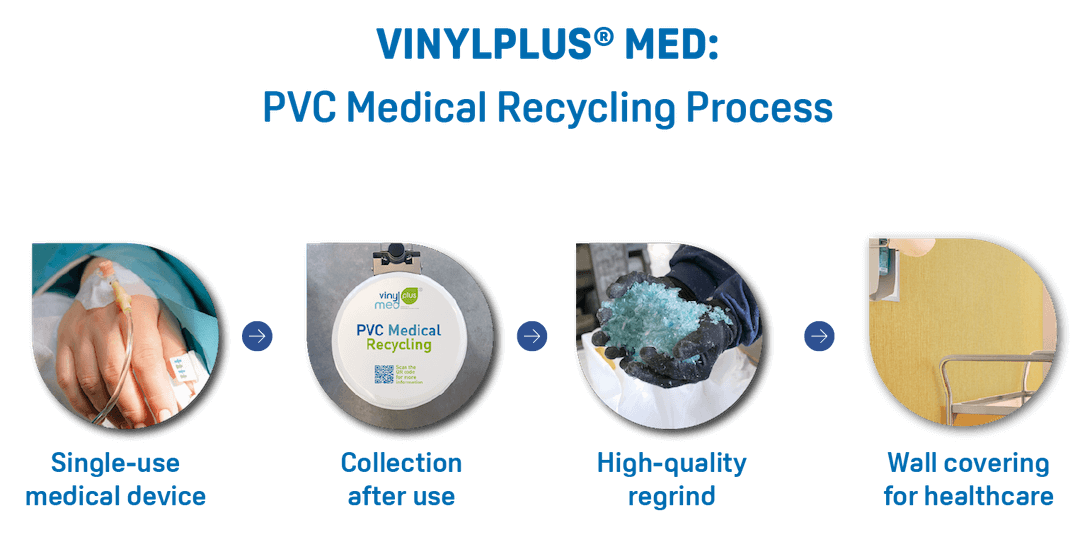

Advancing circularity in the healthcare sector

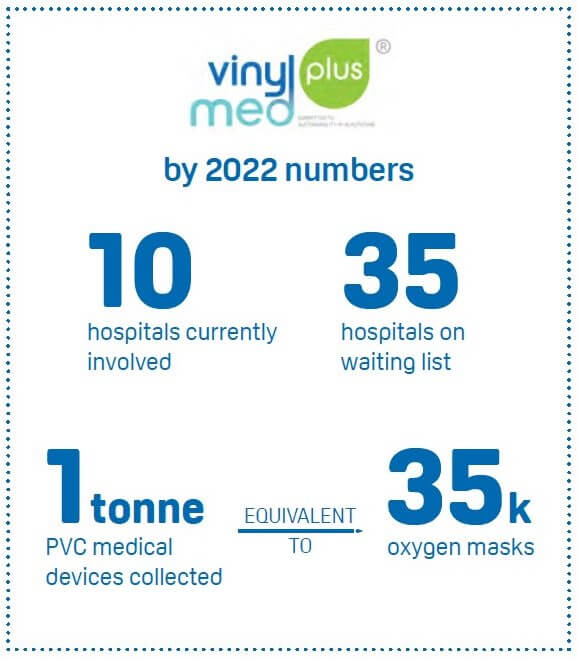

VinylPlus® Med was initiated in February 2021 to accelerate circularity in healthcare across Europe through the recycling of discarded single-use PVC medical devices. A pilot project was launched in Belgium partnering with Renewi as the waste management company, Raff Plastics as the recycler and VinylPlus for the European PVC industry.

Initially launched at Europe Hospitals, the VinylPlus® Med pilot project extended its base to 10 hospitals in 2022.

Preliminary tests run in 2022 showed that the collected medical devices can be turned into high-quality recyclates through energy efficient and environmentally positive processes, and that the recyclates can be reprocessed into long-lasting products for the healthcare sector such as wall covering and flooring.

To ensure that the collected devices do not contain SVHC (Substances of Very High Concern), a new handheld, cost-efficient NIR device was developed in collaboration with Phoenix, which is able to sort out soft PVC waste containing orthophthalates.

The prototype was validated with 45 transparent soft PVC samples of known plasticiser composition.

The first unit was manufactured and delivered in December 2022.

31 different recovery options investigated since 2000

Assessing chemical recycling technologies

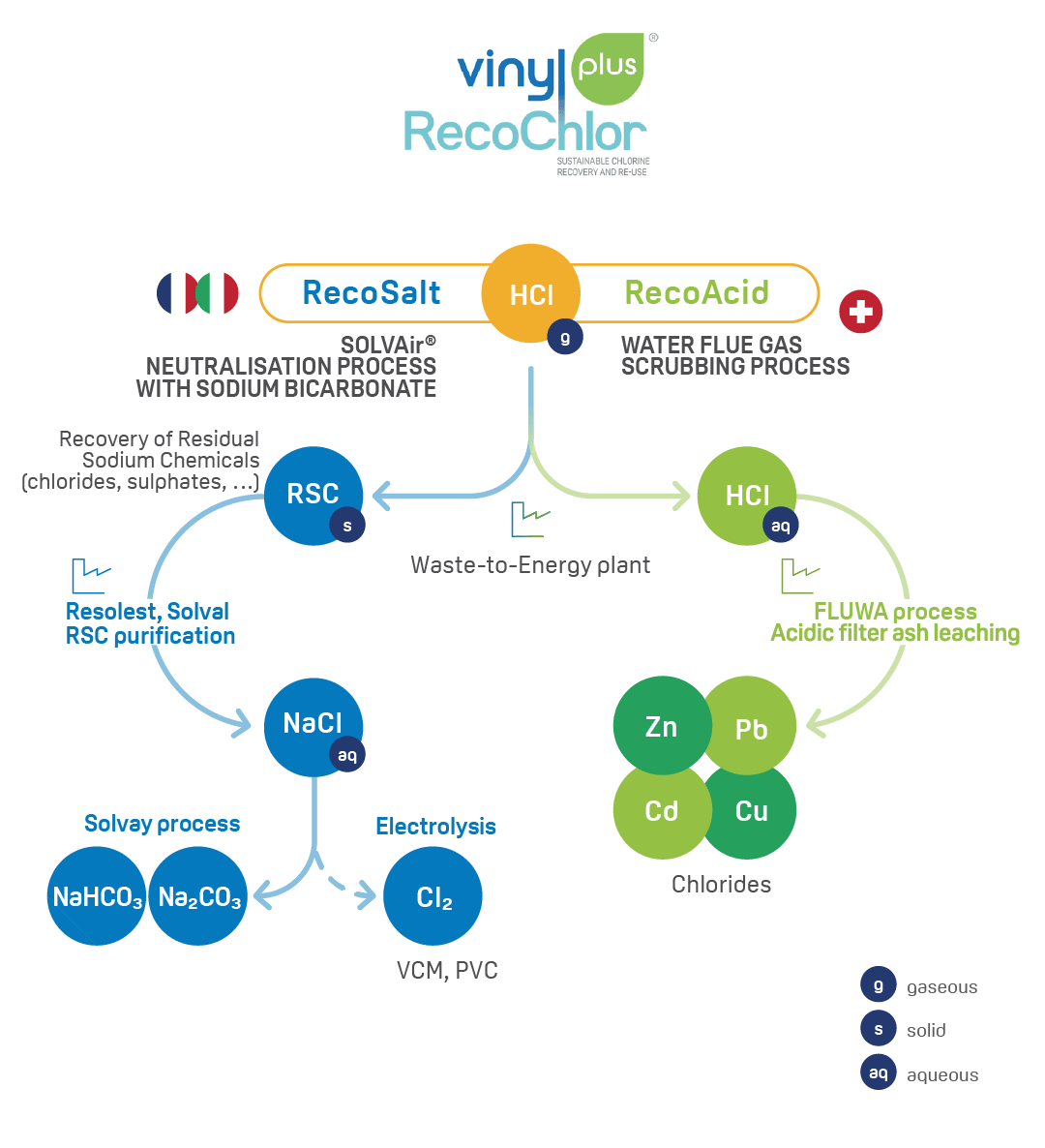

VinylPlus® RecoChlor is a programme dedicated to the PVC waste treatment methodology to recover and recycle chlorine from difficult-to-recycle end–of-life PVC products. This chemical recycling process leads to the production of hydrochloric acid (HCl) in waste-to-energy treatment plants, which is then reused to obtain new products. It includes two major projects leading to the recovery and reuse of chlorine: RecoSalt and RecoAcid (previously named Vinyl Acid).

The RecoSalt project is based on a chlorine chemical recycling process that was studied at the Oreade-Suez plant in France in 2019-2020. After successful preliminary test results, the chlorine neutralisation technology based on the SolvAir® process was selected for further trials.

Based on the FLUWA technology, RecoAcid focuses on additional HCl generation from PVC wastes that are not suitable for mechanical recycling. It involves Swiss municipal solid waste incineration (MSWI) plants, since the FLUWA process will be mandatory in Switzerland in 2026.

The scope of the project is to increase the acid production in flue-gas scrubbers and to use the recovered acid for the recycling of heavy metals contained in MSWI filter ashes. The trials carried out in 2022 at the AVAG KVA AG MSWI plant in Thun, Switzerland, showed that non-recyclable PVC waste can be easily accepted in the waste incineration plant. The increased chlorine concentration in the flue-gas did not show any corrosion or other negative effects in the plants.

Trials also confirmed that the chlorine recovered in the wet flue-gas scrubber can be used to extract heavy metals such as zinc, lead, cadmium and copper from the fly ash and that the recovered heavy metals can be recycled.

At the trial completion, it was confirmed that, both from the incineration plant perspective and from an environmental point of view, wet flue-gas scrubbing in MSWI plants is a valid option for the recycling of PVC wastes which cannot be mechanically recycled.

Prioritising circularity through ecodesign

In October 2020, EPPA, ERFMI, IVK Europe and TEPPFA launched product teams to prepare Design-for-Recycling (DfR) guidelines for their sectors.

The first draft guidelines applicable to PVC windows and doors were presented to the industry at the end of 2021. Based on three pillars (recyclability, recycled content and quality of the finished product), they provide guidance to developers in charge of the design of new products. They detail the many requirements to be fulfilled for a PVC product to be classified as ‘designed for recycling’.

In 2022, all EPPA member companies certified with the VinylPlus® Product Label were trained and accompanied in implementation of the guidelines.

This one-year industrialisation phase provided practical experience that can be incorporated into the guidelines.

In the meantime, the guidelines are also serving as a basis for the development of a European design-for-recycling standard.