Progress Report 2023: Pathway 2

To evaluate the potential and, by 2025, report on projected progress on core carbon reduction to be achieved by 2030, VinylPlus started the selection process for a consultant in 2022. The selection is expected to be finalised by June 2023.

In this context, VinylPlus is also preparing a tender to produce reports, based on scientific evidence, on the uses of renewable energy and sustainable sourcing of feedstock. The reports will be produced by 2025.

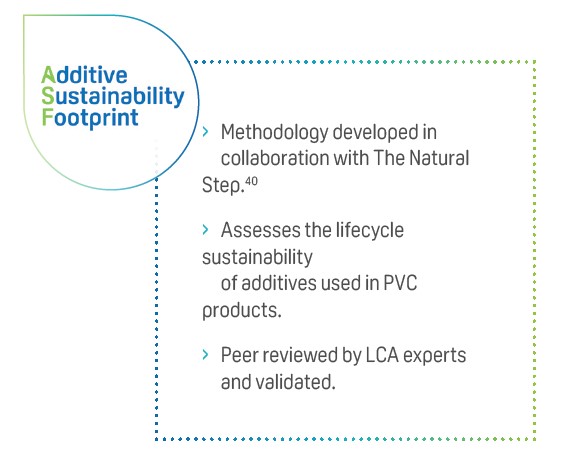

The Additive Sustainability Footprint® (ASF) is a methodology to proactively assess and promote the sustainable production and use of PVC additives throughout entire product lifecycles, including the roles of additives in the performance of PVC products.

Assessing the use of PVC additives into an article with the ASF methodology allows additives producers to increase their scoring for the VinylPlus® Supplier Certificates and facilitates the awarding of the VinylPlus® Product Label for manufacturers of B&C products.

As part of the commitment to spread the knowledge and benefits of the ASF methodology among European PVC converters and to extend the adoption of the ASF and VSCs outside Europe, the methodology was presented at several events in 2022: the 3rd Annual PVC Compounding & Production Cycle Forum; the PVC Formulation event in Cologne, Germany; the 3rd PVC4Cables Conference in Bologna, Italy; and the ASEAN PVC Conference in Bangkok, Thailand.

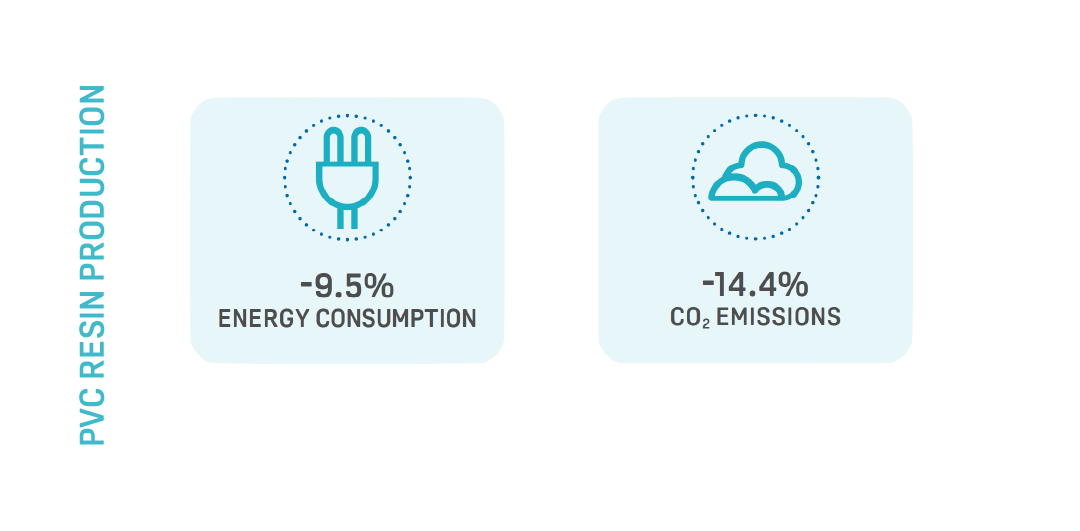

All ECVM members are committed to the continuous reduction of their environmental impact in conformity with the requirements of the ECVM Industry Charter for the Production of Vinyl Chloride Monomer and PVC, updated in 2019.

A third-party verification of compliance with the criteria of the 2019 version of the ECVM Charter was carried out in 2022 by the third-party certification body DEKRA GmbH. Forty plants owned by the ECVM members were audited based on 2021 data; an overall compliance rate of 89% was observed.

A new verification, covering 2023 data from plants that failed to reach full compliance in 2022 and plants from the new member that joined in 2022, will be scheduled for early 2024.

A third-party verification of compliance with the criteria of the 2019 version of the ECVM Charter was carried out in 2022 by the third-party certification body DEKRA GmbH. An overall compliance rate of 89% was observed, despite more-stringent criteria than the BAT-AELs (Best Available Technics-Associated Emission Limits) described in the relevant BREFs (BAT Reference Documents

A third-party verification of compliance with the criteria of the 2019 version of the ECVM Charter was carried out in 2022 by the third-party certification body DEKRA GmbH. An overall compliance rate of 89% was observed, despite more-stringent criteria than the BAT-AELs (Best Available Technics-Associated Emission Limits) described in the relevant BREFs (BAT Reference Documents).

A new verification, covering 2023 data from plants that failed to reach full compliance in 2022 and plants from the new member that joined in 2022, will be scheduled for early 2024.

To help the PVC industry sectoral organisations set up appropriate indicators for the reduction of the water footprint in processes and products, VinylPlus invited EurEau (the European Federation of National Associations of Water Services to take part in a meeting in April 2023. EurEau will help the PVC industry in defining the key criteria to be monitored.

Operation Clean Sweep® (OCS) is an international programme designed to prevent the leakage of plastic granules (pellets, flakes and powders) and help keep this material out of the marine environment. VinylPlus signed up to an OCS commitment which it can carry out itself, namely “encouraging its partners to pursue” the six OCS objectives. All ECVM member companies have signed up to the OCS programme.

With the objective of collecting and mapping the certification schemes used by the upstream supply chain, VinylPlus approached in 2022 Euro Chlor and PetroChemicals Europe, the two sector groups of Cefic (the European Chemical Industry Council) representing the European producers of raw materials for PVC resins. Joint meetings have been scheduled to work on the production of an inventory by the end of 2024.

PVC eyelets and grommets are used in a wide range of applications and sectors such as truck tarpaulins, boats, pool covers, B&C, tents shelters, etc. Our customers sell solutions built to withstand in extreme situations worldwide and are often exposed to harsh weather conditions … PVC is the only material that is suitable for high-frequency welding, which ensures that eyelets and grommets do not break from tarpaulins or foil.”

Claus Ishøy CEO, Carmo A/S